Buckets

Simatek Bulk Systems A/S offers a number of different bucket qualities meeting various requirement of the industry i.e. product features, physical conditions, temperature and sanitary requirements. Simatek elevator

buckets are divided in the following categories:

- Injection moulded buckets in various plastic qualities: antistatic, detectable, food approved

- Thermoformed buckets in various plastic qualities

- Steel buckets in various steel qualities

Standard Buckets

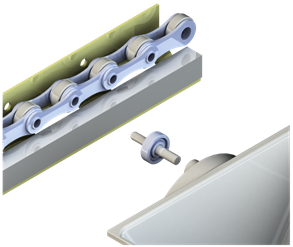

Our standard buckets are produced in injection moulded plastic, with bucket overlap and an integrated gable ring for a mechanical,forced controlling system.

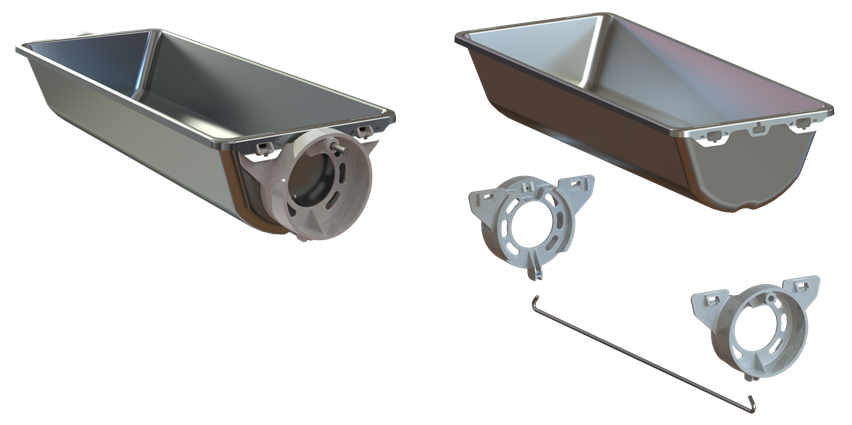

Buckets without overlap (FRB)

Buckets without overlap have limited mechanical, forced controlling, and for the thermoformed versions there are replaceable gables. Buckets without overlap are used only in connection with the Simatek Drum Feeding System (Continuous Batch Feeding System) where the buckets are filled separately.

Replaceable gables

When using buckets without overlap and with replaceable gables the maintenance costs will be reduced significantly.

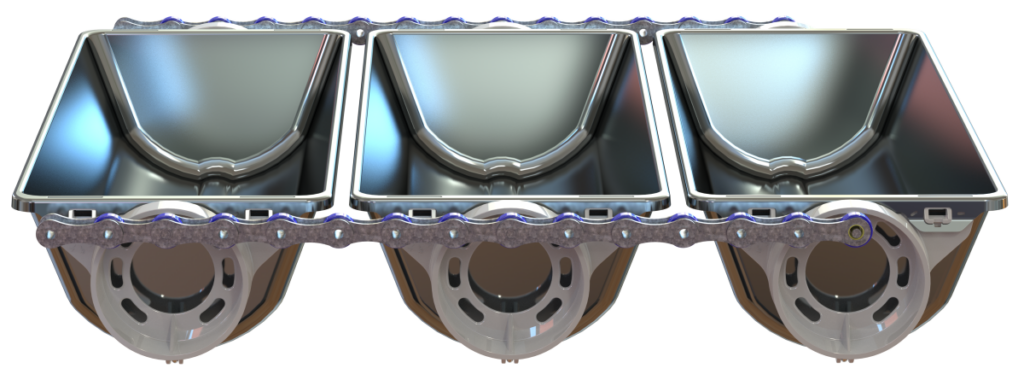

Bearing suspended buckets

FRB with bearing suspension is ideal for abrasive products. The closed and lubrication free bearing construction generates less friction and has a documented 40% power consumption reduction. Wear on the roller chain is basically eliminated when conveying with bearing suspended buckets.

Split buckets

Split buckets are used for simultaneous conveying of two product types or qualities in the same elevator bucket. Split buckets may be a good solution for the sorting and separation processes where separated product fractions must be conveyed in the same elevator.